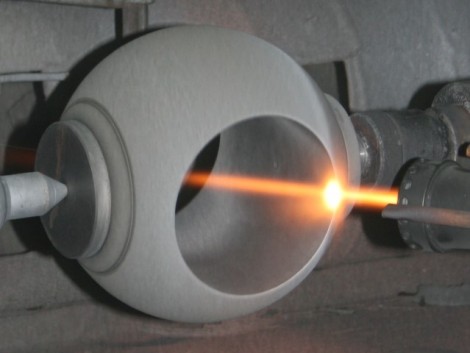

HVAF

As part of Harfords services, we offer HVAF coatings. This process uses air and fuel gases to spray metal and carbide powders at supersonic velocities exceeding 2300 ft/s, with particle temperatures remaining slightly below the melting point of metal and metallic binders meaning the HVAF process operates in a solid-state spray mode. During the integration of this system, Harfords noted that the HVAF coatings were radically different to our HVOF coatings. Harfords noted the following benefits with HVAF;

- The coating did not exhibit voids and imperfections

- All particles are tightly bonded together

- A higher bond strength

- Lower oxide content

- Increased wear, corrosion and fatigue resistance

- Increased thickness of Carbide can be applied

Components Repaired

- Ball Valves up to 2mm thickness

- Ball Valve Seats

- Seal Journals

- Discharge Nozzles

- Cheek Plates for briquette apparatus

- Augers

- Valve liners up to 4mm thickness

- Butterfly Valve Discs and liners

- Wood Chipper Blades

- Bearing Housings

- Gas Turbine – rotating sleeves

- Paper and Pulp – sorter rolls

- Sub-Sea ball valves and seats

Research Driven Coatings

Tungsten carbide-cobalt coatings are alternatives to chrome plating on high-strength steel landing gear components. In independent testing conducted by a US Air Force Research lab the WC-17Co AC-HVAF coatings outperformed all HVOF counterparts in fatigue testing at increased loads and especially when thicker layers were applied, meeting the metallurgical criteria established by General Electric Aircraft Engines for HVOF coatings. Engineers rated the AC-HVAF coating as superior to the HVOF coatings and equal to EHC plating.

Due to the forgiving nature of the AC-HVAF process the quality of the applied coating remains largely unchanged at shallow spray angles and a wide range of gas parameters. Only the particles with the proper temperature and velocity characteristics form a coating; the particles with poor adhesion are removed by the grit-blasting effect of the AC-HVAF process. In other words, changing the spray parameters will only affect the deposit efficiency, not coating quality.

HVAF, another of the unique and extensive service offered at Harfords.

Feel free to explore our site to find out more About Us or Contact Us with any enquiry…